01 / 04

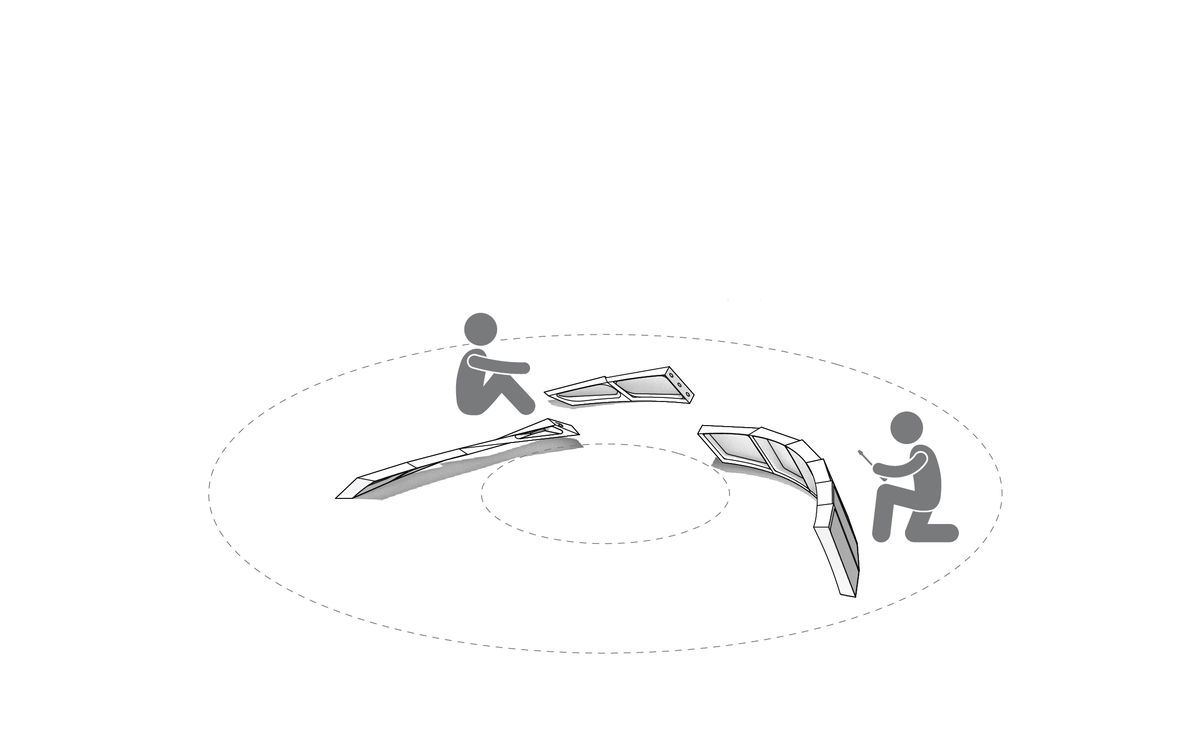

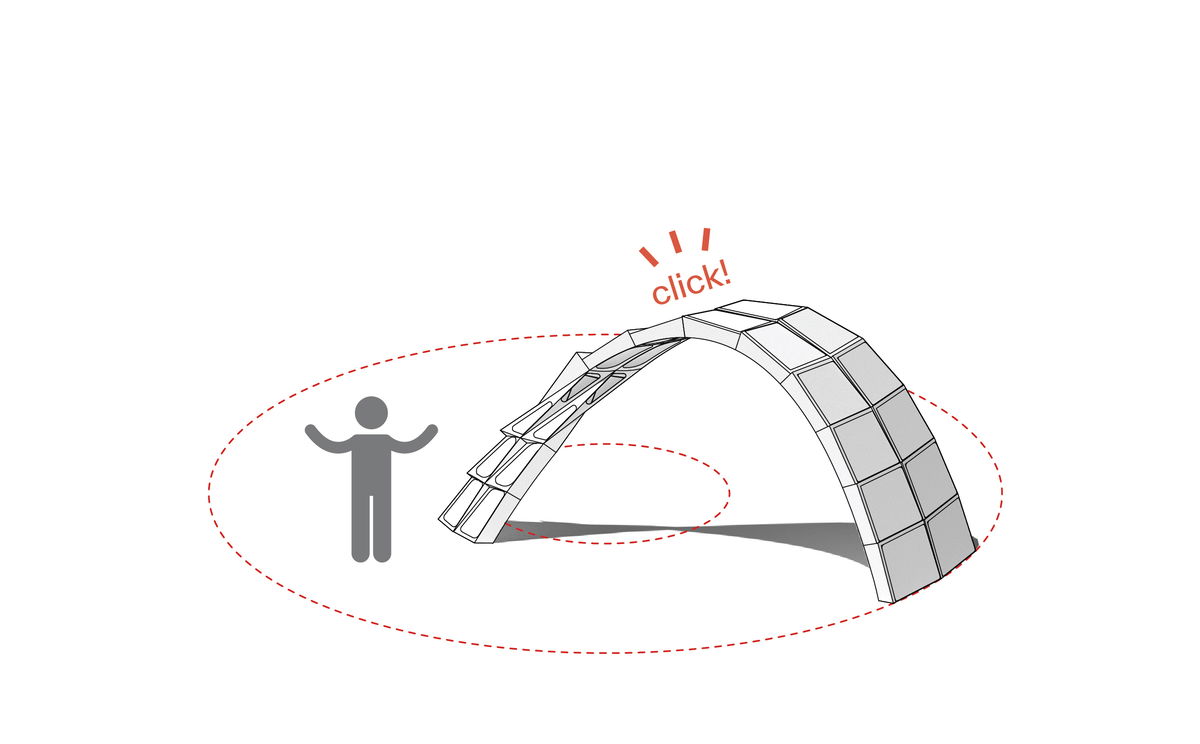

THE FRAME ELEMENTS ARE PRINTED INDIVIDUALLY AND ASSEMBLED INTO A SINGLE ARCH

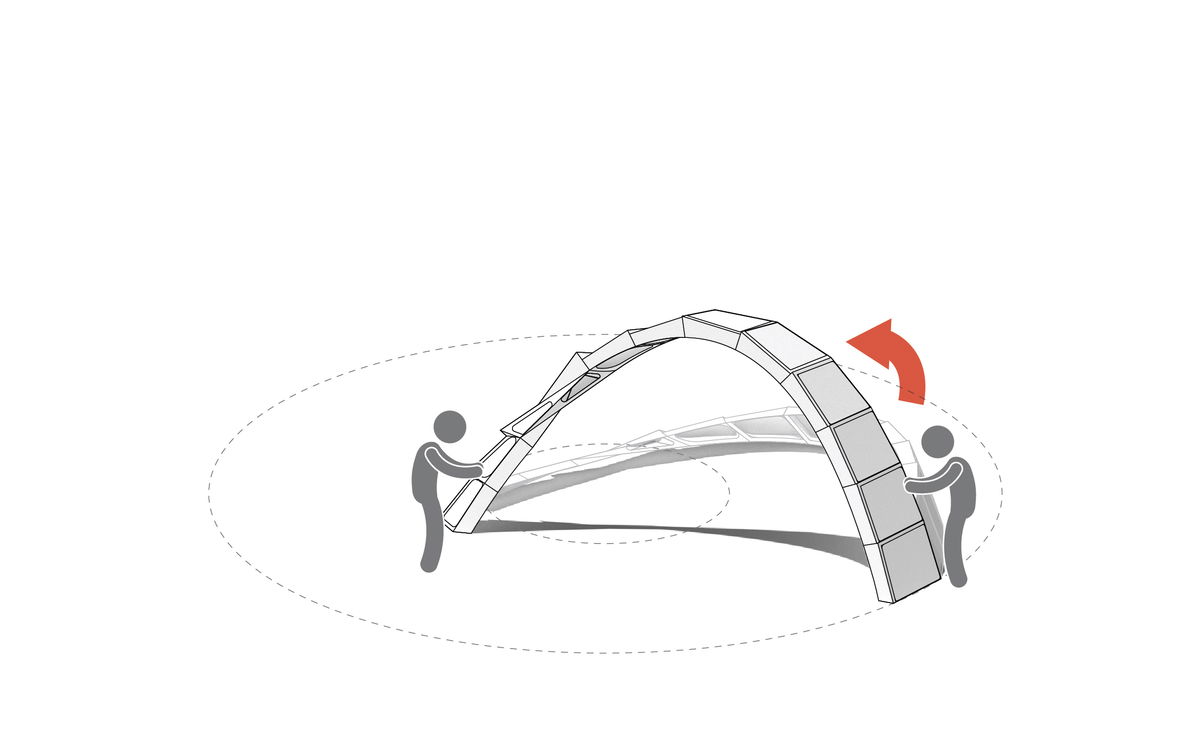

THE ARCH IS LIGHTWEIGHT AND CAN BE ROLLED INTO PLACE BY A SMALL TEAM

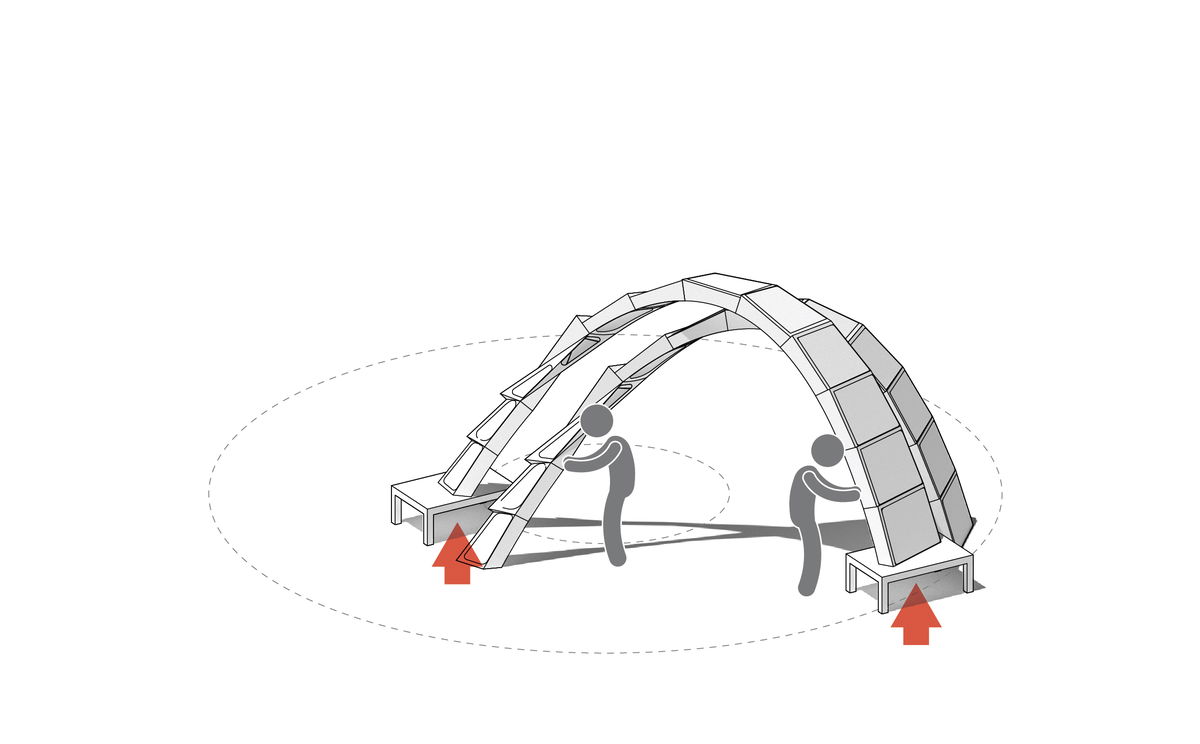

THE BASE OF THE PAVILION IS SECURED BY TYING EACH END OF THE ARCH TOGETHER

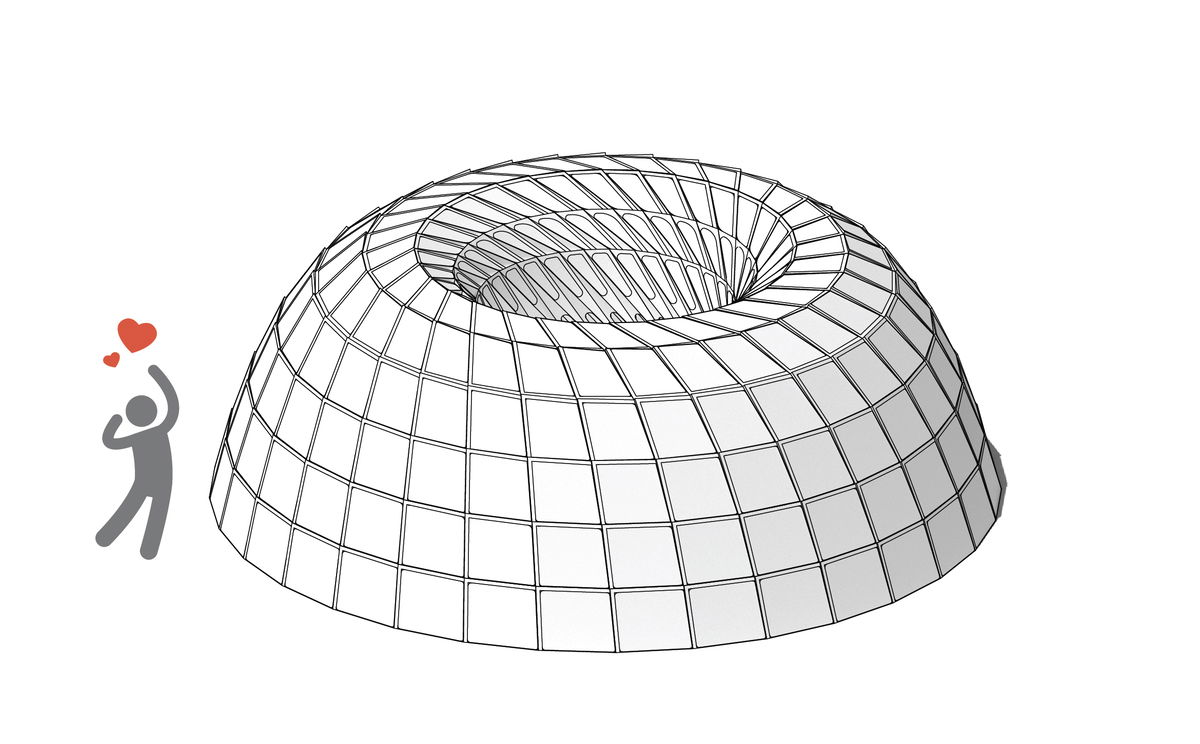

EACH INDIVIDUAL ARCH IS THEN ROTATED INTO PLACE AND JOINED WITH THE ARCH NEXT TO IT

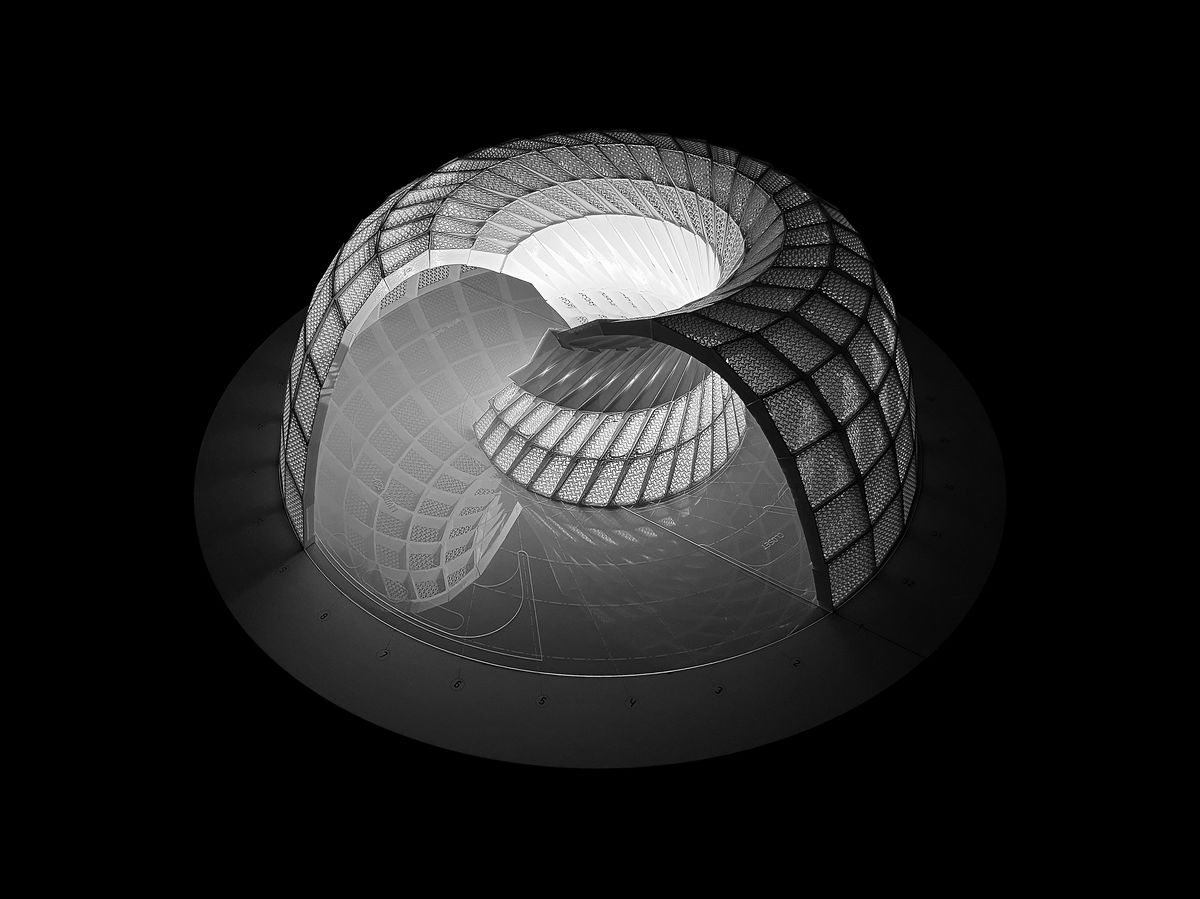

THE COMPLETED I AM MSHRM PAVILION

01 / 05

“In collaboration with AM Hub, we researched and developed a 3D printed deployable, innovative frame system filled with mycelium. The goal has been to develop a new system of building that can do more with less. Less construction waste because printing eliminates the need for molds and scaffolds, less organic waste because our building literally takes trash and turns it into building blocks and less carbon because we have invented a bio-based plastic panel system that optimizes material properties.”Catherine Huang - Partner, BIG

Partner in Charge

Bjarke Ingels

Catherine Huang

Project Manager

Tyrone Cobcroft

Project Architect

Dora Jiabao Lin

Project Team

Desislava Georgieva

Jason Cheuk Hei Lee

Paula Madrid

Alžbeta Hlinová

Jan Kyselý

Tarek Shater

Augusto Lavieri Zamperlini

BIG Engineering

Andrea Hektor

Jens Max Jensen

Pavel Tomek

Lore Vyfeyken

Thomas Lejeune

Johan Fredrik Lindqvist

Collaborators

MDT

Naturpladen