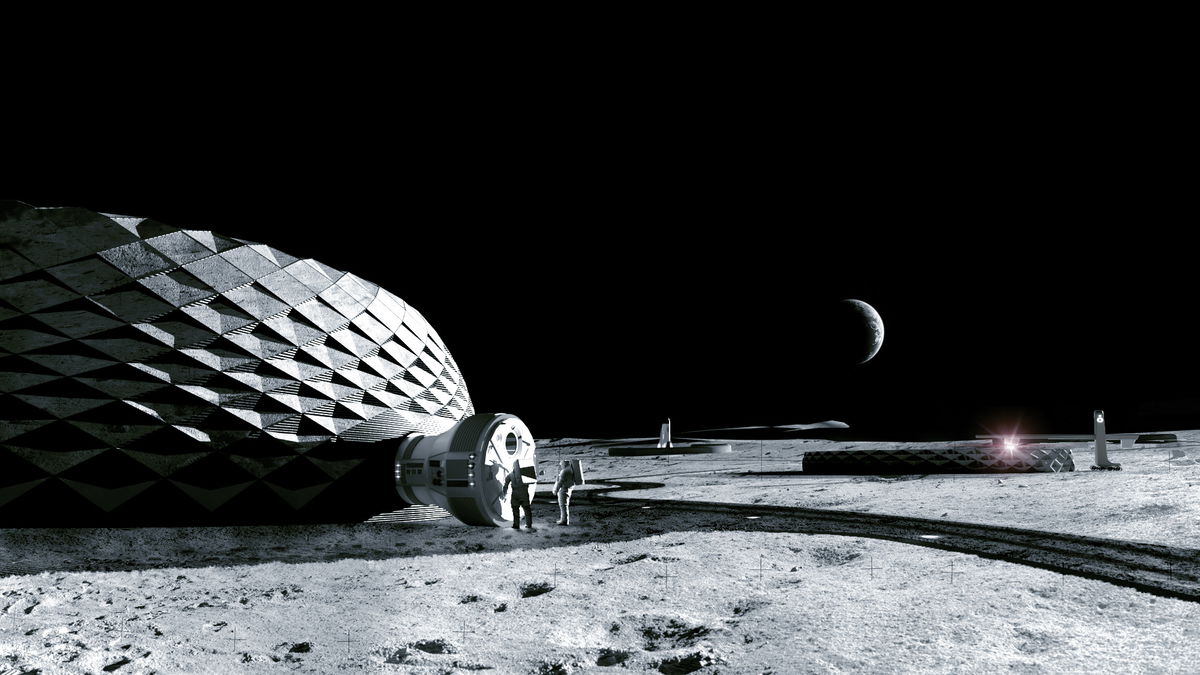

“To explain the power of architecture, "formgiving" is the Danish word for design, which literally means to give form to that which has not yet been given form. This becomes fundamentally clear when we venture beyond Earth and begin to imagine how we are going to build and live on entirely new worlds. With ICON we are pioneering new frontiers - both materially, technologically and environmentally. The answers to our challenges on Earth very well might be found on the Moon.”Bjarke Ingels - Founder & Creative Director, BIG

“The NASA Olympus habitats will be designed with the inherent redundancy required for extraterrestrial buildings, while also using groundbreaking robotic construction that uses only in-situ resources with zero waste left behind. With the technologies and efficiency parameters developed for the construction of extraterrestrial buildings, Project Olympus will also help us build sustainably on planet Earth as we strive to reduce the carbon footprint of the built environment.”Martin Voelkle - Partner, BIG

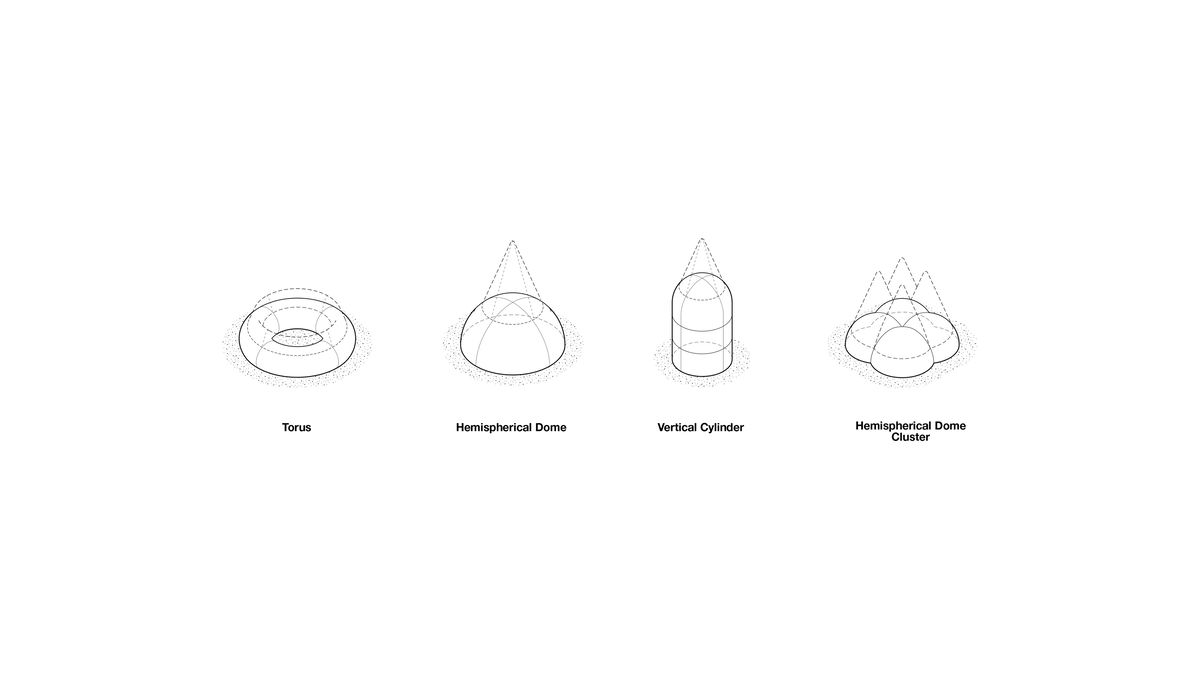

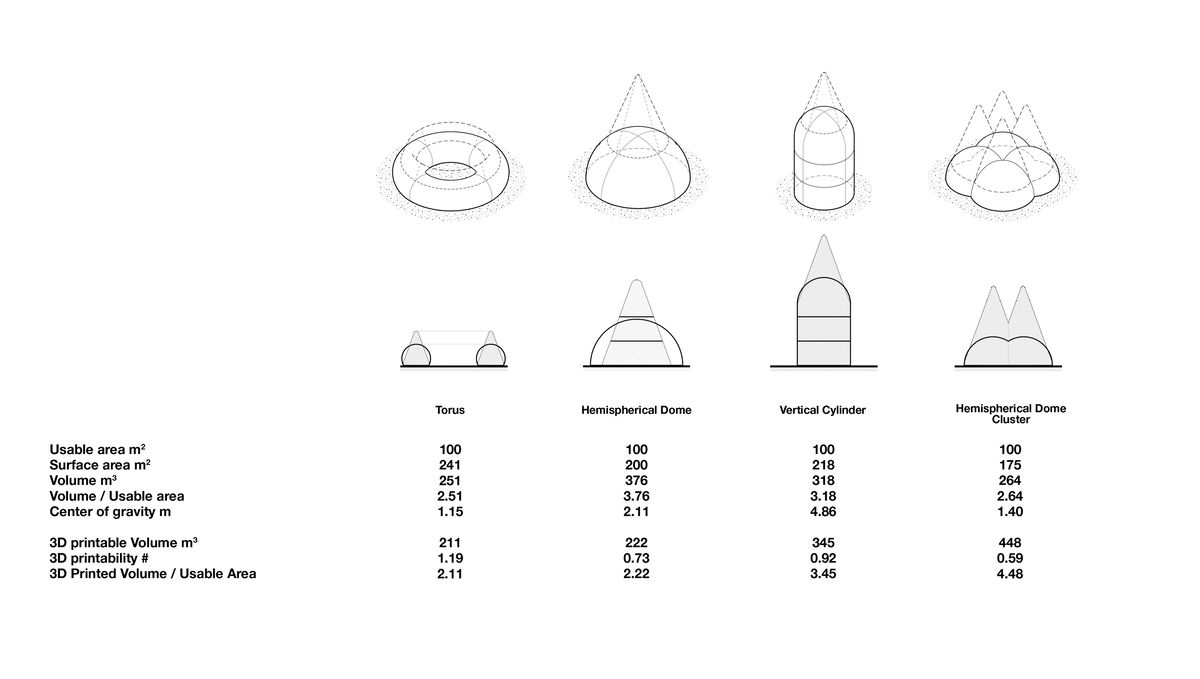

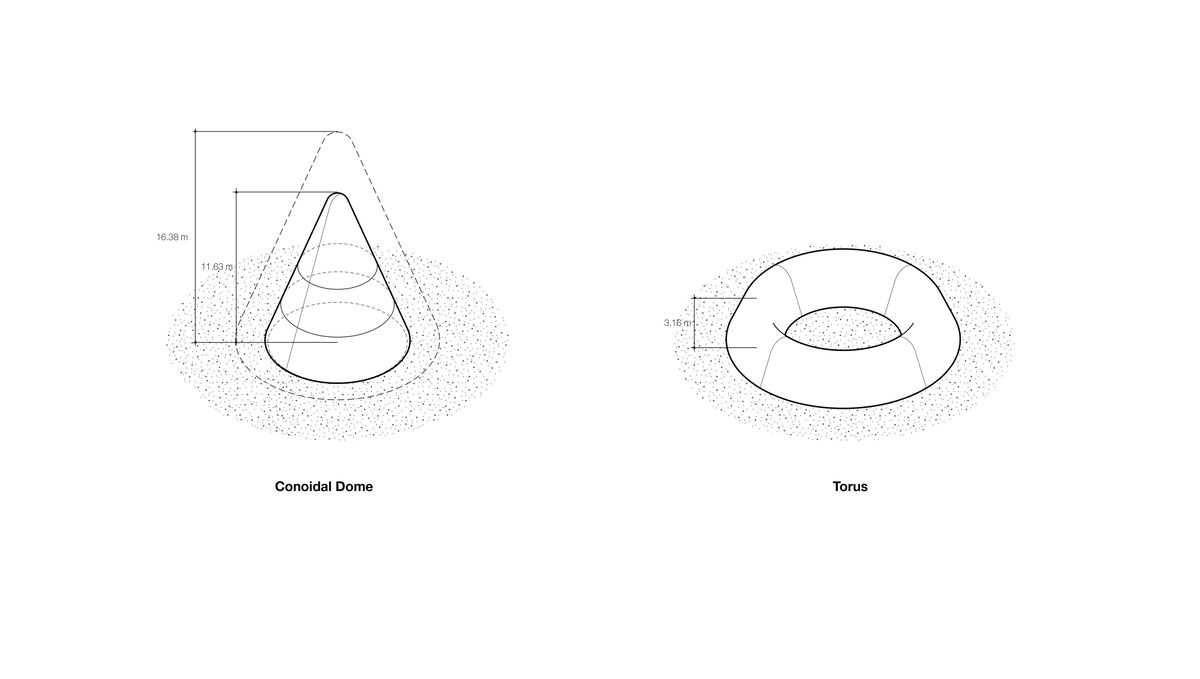

3D PRINTING FORMAL OPTIMIZATION — Shape optimization is needed to reduce printing overhang. Our current working assumption is a 70 degree print max wall incline.

MATERIAL USAGE OPTIMIZATION — Pockets of loose regolith will be introduced as a way to minimize printing time and energy demands while keeping the same level of protection.

IMPACT SHIELD — Using the fish-summer equation, with a meteor size of 7 cm at a velocity of 20 km, it has been estimated that a 45.9 cm wall is required to stop the meteor from penetrating.

THERMAL SHIELD — On the lunar surface, temperatures can vary widely from a day temperature of 123 C, to a night time temperature of -247 C. 0.5 m to 1 m of regolith can mitigate temperature variation and settle it around -27 C.

RADIATION SHIELD — Loose regolith on the exterior of the wall assembly will reduce the overall need for sintering. To block 100% of cosmic rays, it would require a 500 centimeter thickness of regolith.

LOOSE REGOLITH BUCKETS — In order to avoid regolith dispersion during moonquakes and landing/takeoff activities, the structure will trap regolith within the external wall.

PRESSURE — A liquid applied elastomer membrane in the interior face of the 3D printed wall might be needed to ensure the print is airtight and can withstand the pressure difference.

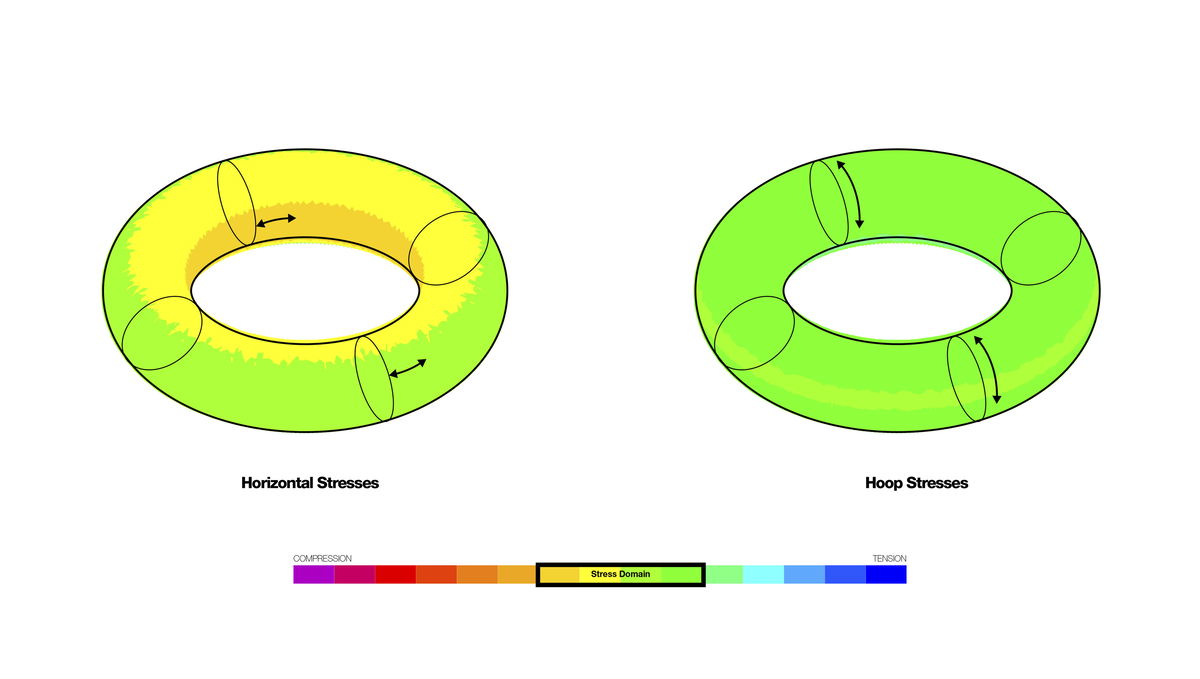

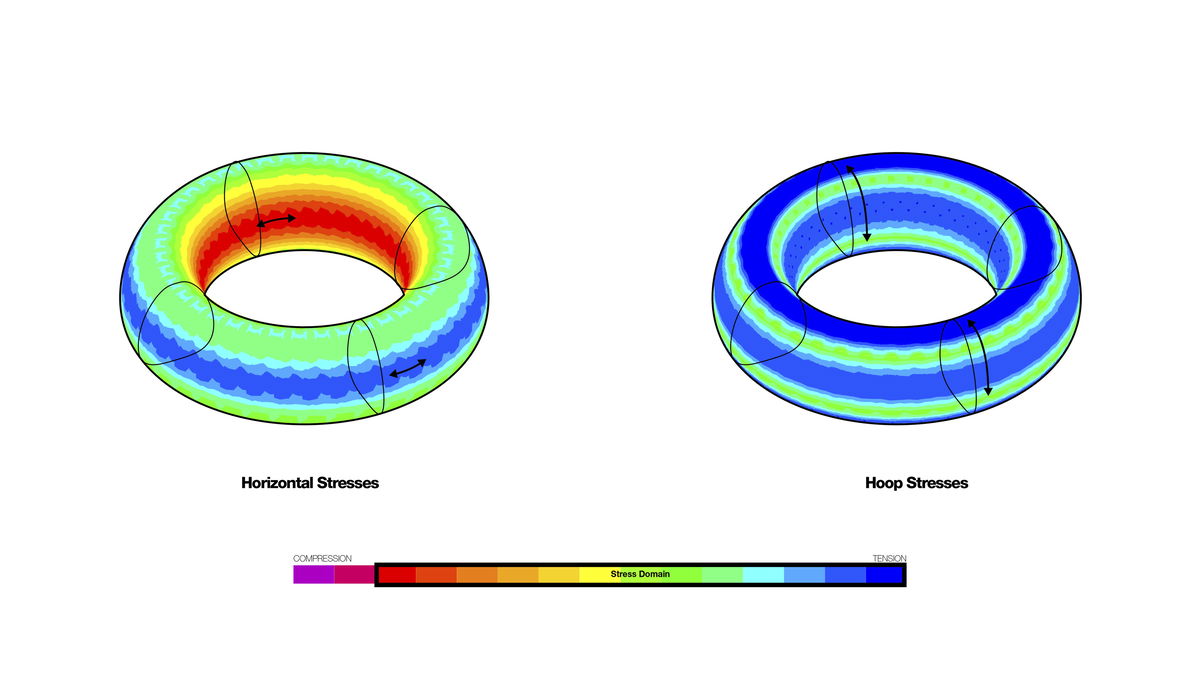

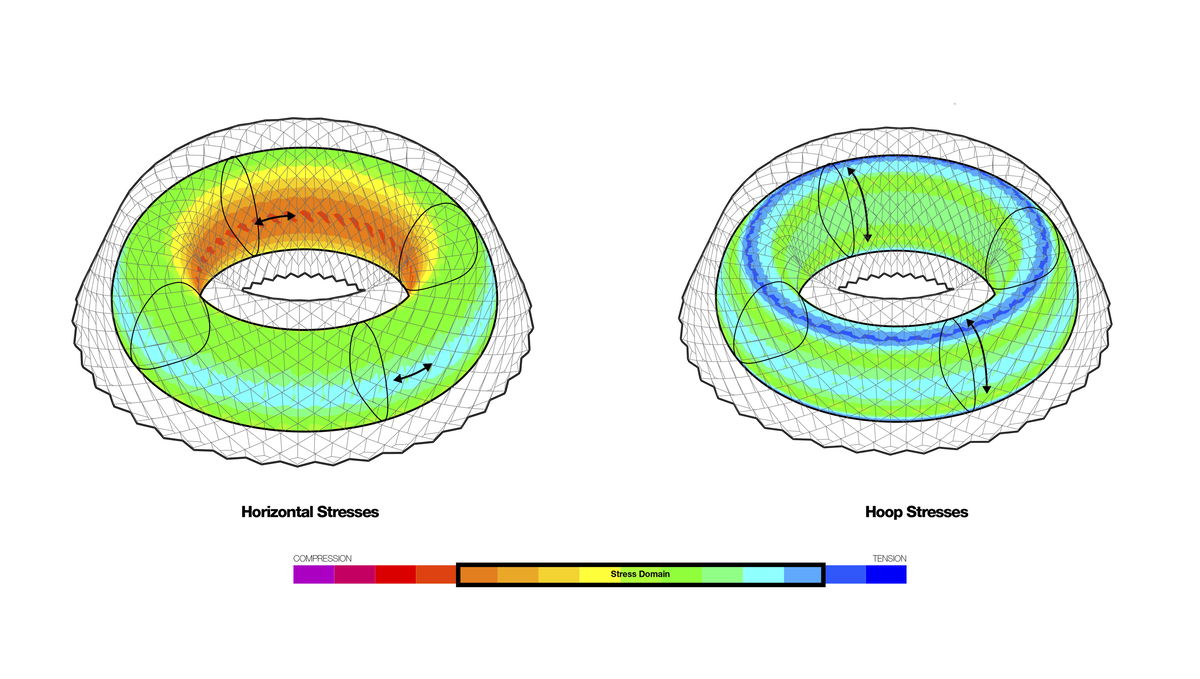

PRESSURE — The ideal line of action for a pressurized structure.

PRESSURE OPTIMIZATION — Exterior structural layer to adopt the rounded shape of a pressurized structure and negotiate between the ideal pressurized shape and the interior printable shape. Further geometry optimization to take place through digital force simulation and benchmark testing.

“Building humanity’s first home on another world will be the most ambitious construction project in human history and will push science, engineering, technology, and architecture to literal new heights. NASA’s investment in space-age technologies like this can not only help to advance humanity’s future in space, but also to solve very real, vexing problems we face on Earth. We are honored to begin our research and development on ICON’s ‘Project Olympus’ and the ‘Olympus Construction System.’”Jason Ballard - Co-founder & CEO, ICON

Partner in Charge

Bjarke Ingels

Martin Voelkle

Project Leader

Julian Ocampo Salazar

Project Manager

Michelle Stromsta

Project Team

Guillaume Evain

Fabian Lorenz

Jenna Dezinski

Siqi Zhang

Rasam Aminzadeh

Beat Schenk

Jaeho Park

Jakob Lange

Collaborators

BIG Engineering